Inspections

Reduce Risk, Time & Cost

Incredible Group’s commercial drones and CAA Part 102 Certified drone operators vastly reduce the risk

and time involved in inspections, compared to physical inspections. Whether you need regular maintenance, inspections/surveys, an urgent or emergency response, we have you covered – Incredible Group is on call 24/7

Safe, accurate & cost effective: drone Aerial Inspections & Surveys NZ-wide.

We obtain all Permissions required, e.g. from local authorities & airfields.

- Buildings, Assets, Utilities & Infrastructure

- Thermal Imaging (Thermographic Imaging)

- CAA Part 102 UAV Certification

- Full Aviation & $10M Public Liability Insurance

- 11,900+ Safety Verified logged flights

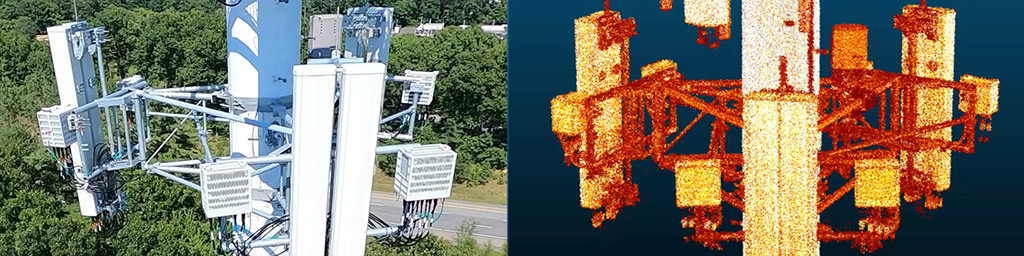

Cell Tower Inspections

Drone technology is disrupting entire industries, and it’s finding its use in the telecommunication industry. Due to their nature, cell towers inspection are a difficult endeavour. In order to perform a cellular tower inspection, workers have to risk their lives, potentially disrupt tower performance, and climb high-rise platforms. With drones, there is no need to cause downtime or endanger workers.

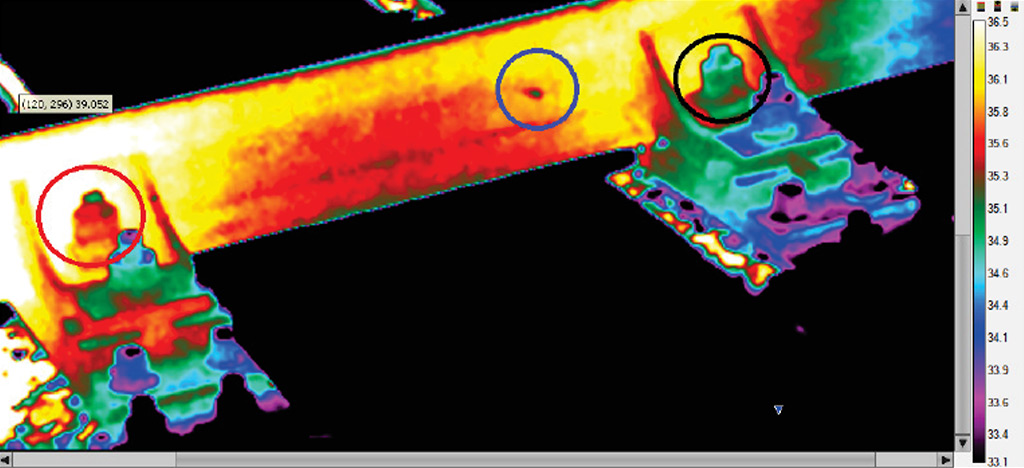

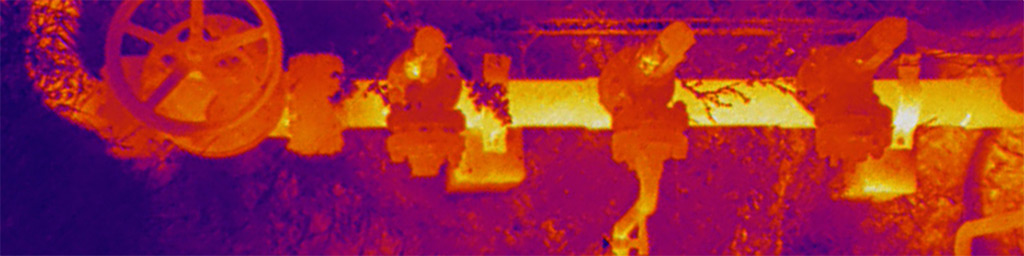

Drones can capture high-resolution images & videos in a matter of minutes. The footage can be zoomed in and any faults on tower or antennas can be easily detected. Thermal imagery cameras can be used to detect any energy loss and potential performance issues. There are certain pieces of the cell tower that are expected to produce a certain amount of heat. Thermal sensors can determine if this equipment is within tolerances regarding heat production. They can also show the maintenance team where potential problems may lie.

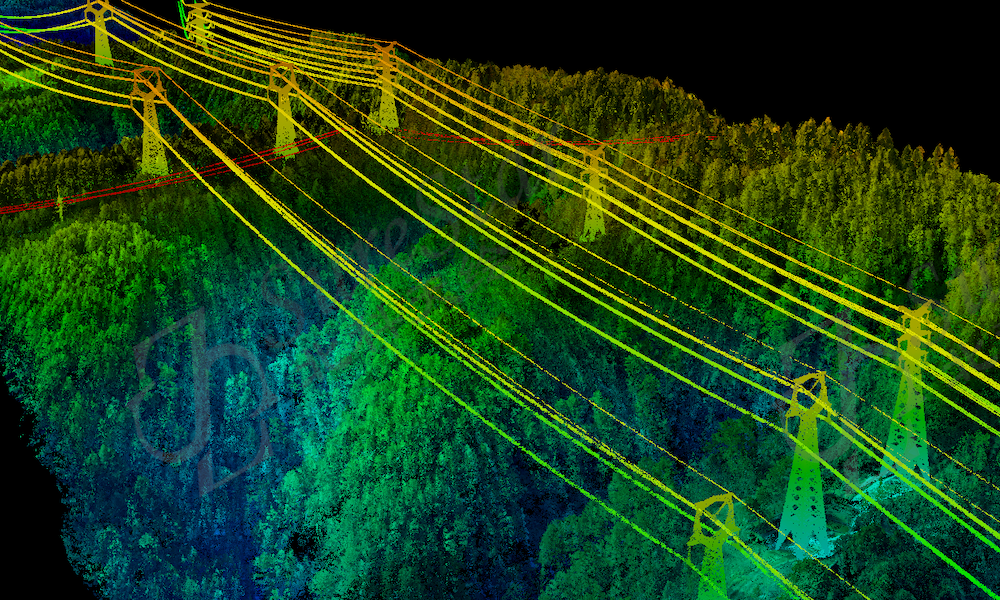

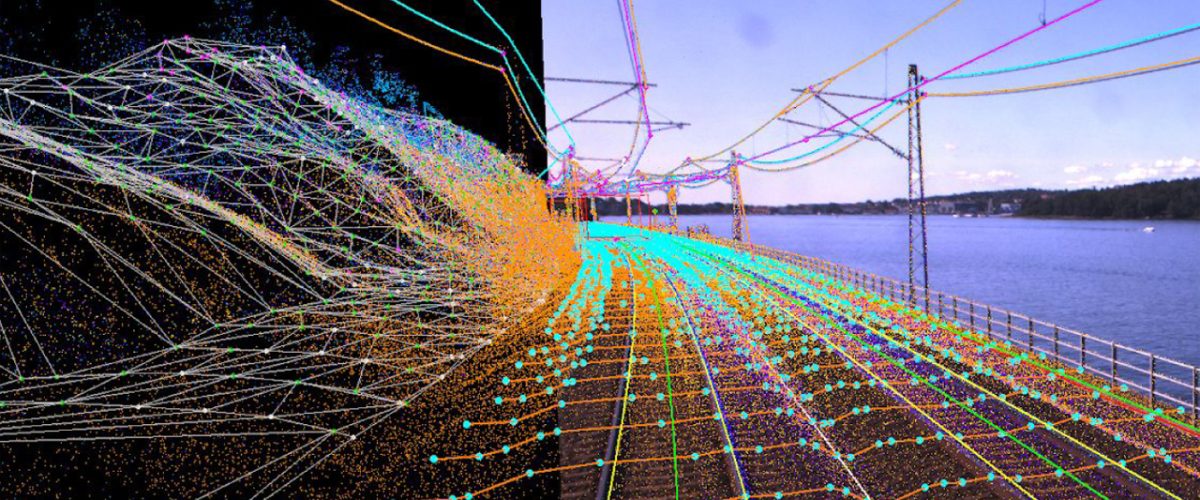

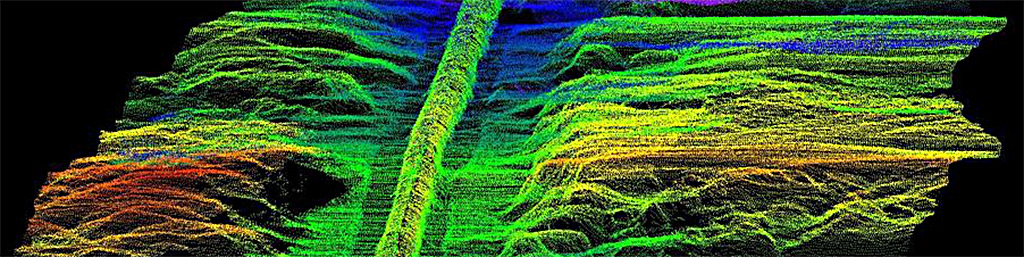

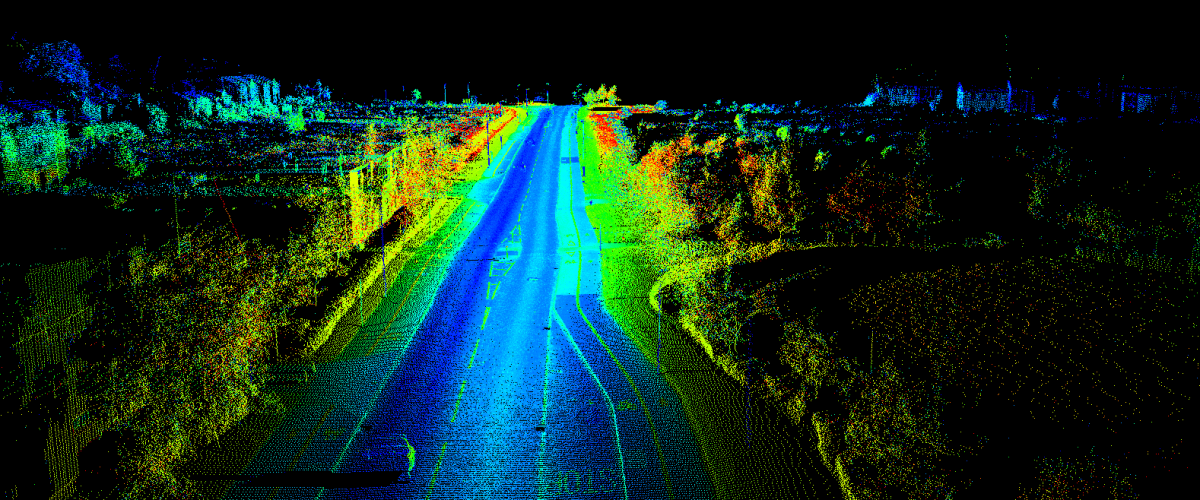

Dedicated LiDAR sensors employ the use of laser emitted light. This, in turn, produces a rather rich data set that can be used in the production of high-resolution maps, as well as detailed 3D models of the entire site, or just the tower itself. Drone LiDAR collection sets yield the highest quality data in form of a point cloud. This point cloud can effectively measure hundreds of points per square meter of space measured at a vertical elevation accuracy of 2 to 3 centimetres. This allows for a precise measurements purely based on the inspection data.

When performing these drone cell towers inspections, the imagery and data packages can more than pay for the service. Also, by using a drone, you are getting a permanent record of the inspection that can be referred to time and time again — unlike when there are only the inspector’s eyes for information.

Using drone technology for cell tower inspections we can virtually eliminate accidents that are incurred by the dangers of climbing to inspect the tower. Inspect your telco cell towers without danger to employees and quickly detect malfunctions

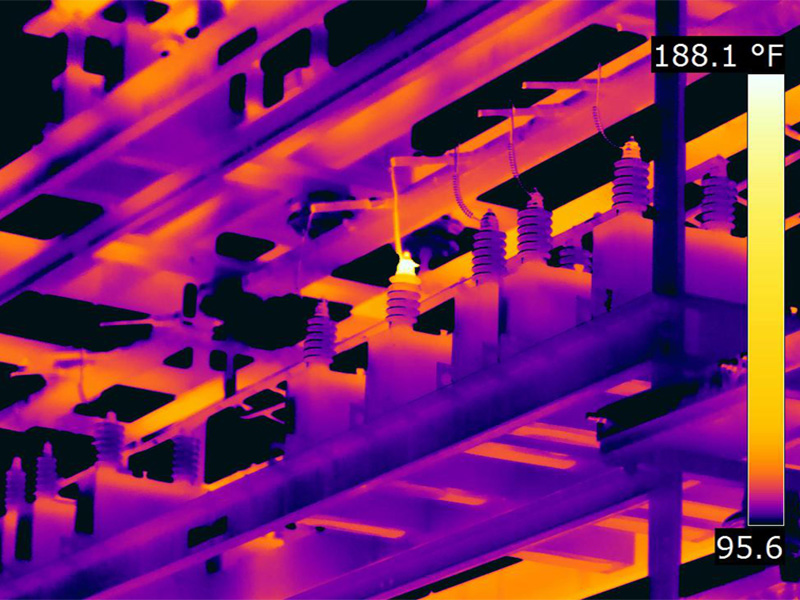

Power Lines Inspections

More utilities are recognising the value of drone technology for power line inspections. Advanced drones can conduct assessments in hard-to-reach areas, and Beyond Visual Line of Sight (BVLOS) capabilities allow operators to navigate drones beyond their line of sight, accessing challenging or high-risk locations. Though BVLOS operations require experienced, highly qualified pilots and specialised licenses, they provide a safe, efficient solution that is less dependent on weather conditions than manual inspections.

Drones are ideal for identifying potential issues such as bird nests, lightning damage, rust, and loose bolts on power lines and pylons. Our drone systems are equipped to manage magnetic interference from power lines, enabling close-range flights that capture high-resolution images and valuable data essential for fine-tuning maintenance plans.

By detecting hotspots early through thermal imaging, utilities can prolong the life of equipment, avoid failures that could cause widespread outages, and reduce costs by performing preventive maintenance instead of costly replacements. Thermal imaging reveals issues invisible to the naked eye, allowing timely repairs that benefit the entire grid.

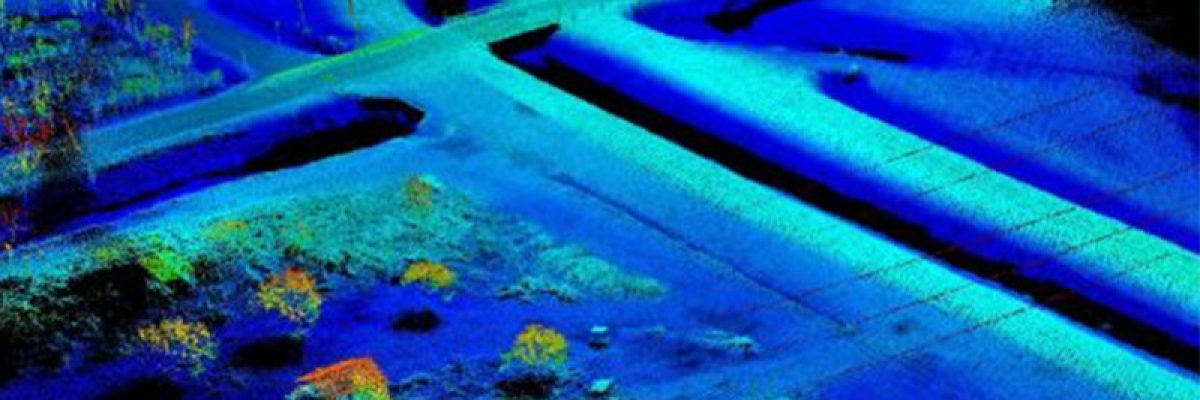

Using LiDAR technology, drones create precise 3D maps and point clouds that measure the proximity of vegetation to power lines. This data helps grid operators identify and prioritise at-risk areas, enabling them to focus vegetation management efforts where they are most needed. In post-storm inspections, LiDAR can detect tilting or damaged trees near power lines, allowing preemptive action to prevent blackouts from falling debris. LiDAR inspections save time, reduce maintenance costs, and minimise revenue loss by avoiding service disruptions.

Based on photos captured during drone flight, RGB data analysis enables distribution and transmission system operators (DSOs and TSOs) to detect otherwise hard-to-spot defects, such as broken wires, rust, and damaged insulators. Drones provide an aerial view of power poles and lines, enabling a comprehensive assessment of asset conditions. This fast, accessible inspection method is helping more utilities adopt efficient, top-down asset monitoring.

Infrared imaging is also essential in power line inspections, identifying overheating components and corona effects. Overheating indicates potential failure risks, prompting immediate attention to prevent outages and grid downtime. Thermal images reveal hot spots that stand out against surrounding elements, allowing grid operators to act quickly and maintain grid stability.

Railways Inspections

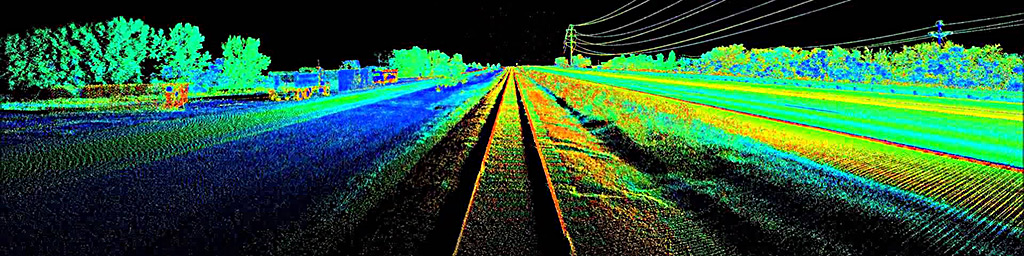

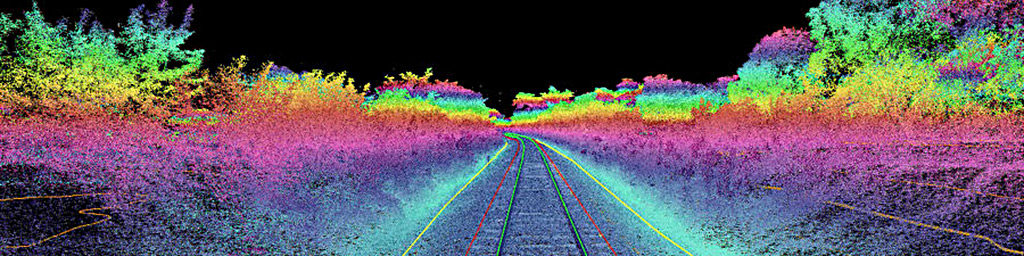

Drones have become essential for reliable railway inspections and critical in monitoring key infrastructure such as high-voltage electrical lines, railway catenary lines, tracks, and switching points. Drone technology enables the rapid collection of detailed imagery, accelerating defect detection for cracks and structural hazards. More frequent inspections enhance railway safety, reliability, and schedule adherence. This increased productivity reduces costs and boosts overall industry performance.

Oil & Gas Inspections

Solar Panels Inspections

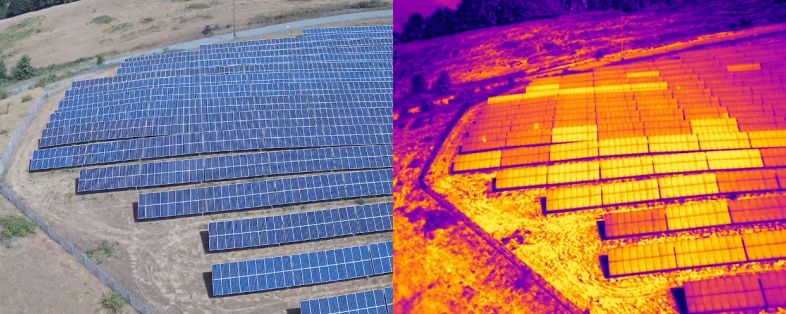

Aerial inspections enable comprehensive documentation and diagnosis of panel degradation, inverter scans, and vegetation management—tasks often limited in scope by traditional inspections, which typically sample only part of a site. In contrast, drones cover entire solar projects quickly and efficiently.

UAV technology for solar panel inspections is ideal for energy providers, renewable asset managers, and governmental agencies focused on sustainable energy solutions. Drones improve installation reliability and efficiency, eliminating the safety risks of manual inspections where workers may have to climb rooftops, navigate challenging terrain, or endure extreme weather. Drone inspections are safer and more cost-effective, avoiding the high expenses associated with time-intensive manual methods.

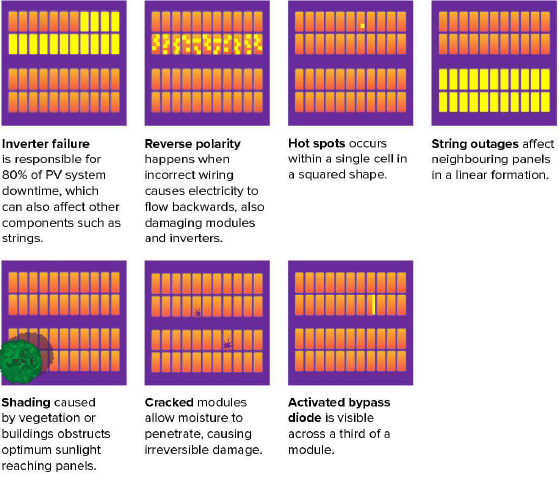

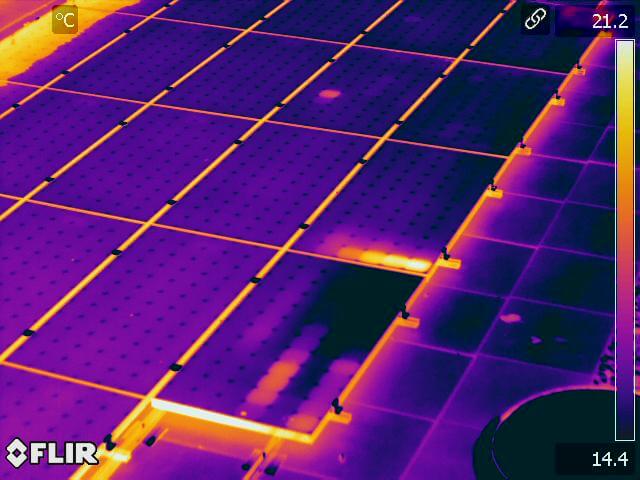

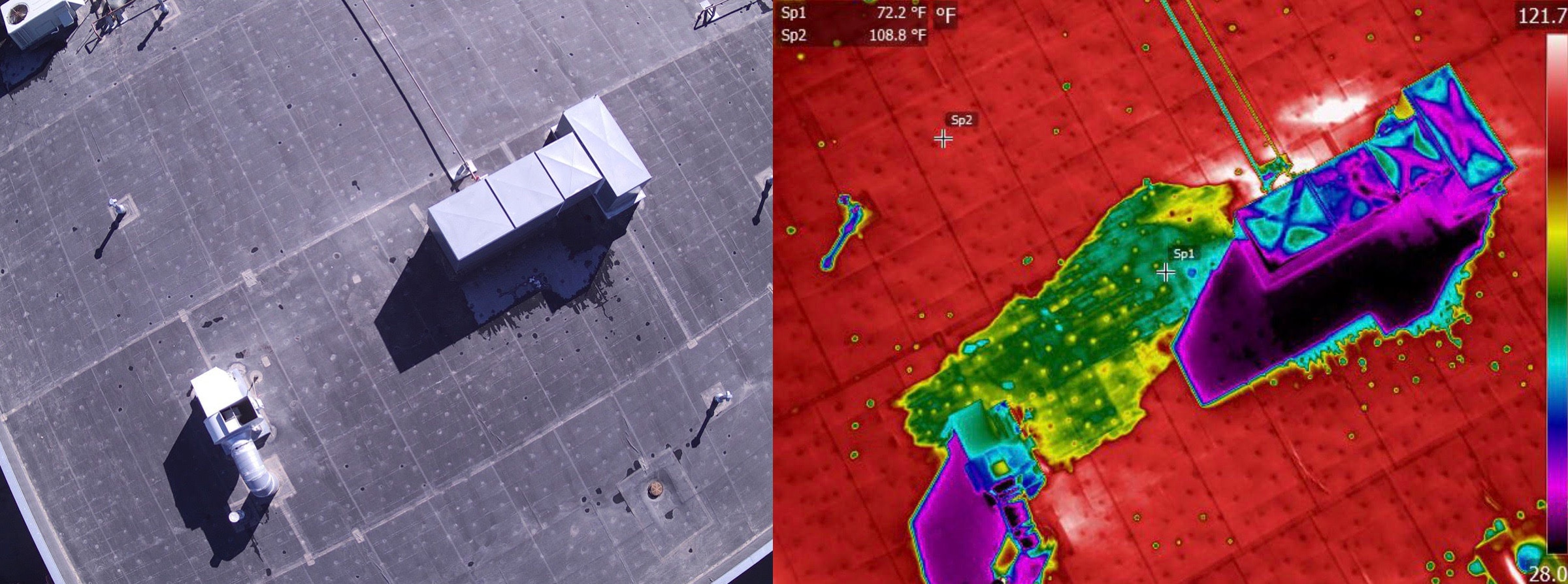

Using aerial thermal imaging, drones can swiftly detect and diagnose faults in areas where electricity production has dropped, allowing asset owners to address operational inefficiencies and optimise output. Drones can identify issues such as cell and string defects, faulty diodes, debris, inverter malfunctions, and short circuits. These inspections are faster and more precise than manual checks, reducing the risk of technician injuries. Drones can quickly inspect large solar installations, reaching hard-to-access areas like rooftops or expansive solar fields, and cover vast areas in less time, saving resources and reducing operational disruptions.

Drone-based solar inspections and monitoring offer a fast, accurate, and cost-effective way to ensure peak panel performance. Regular thermal inspections can reveal emerging issues early, enabling timely maintenance and avoiding costly repairs or replacements. Tracking trends in detected anomalies over time can also enhance system efficiency and reduce long-term maintenance costs.

The future of drone technology in solar energy is bright, with continued advancements expected to improve solar installation efficiency further. Drone hardware and software developments are already enhancing panel placement and inspection accuracy and precision. Future innovations could lead to drones autonomously performing maintenance tasks and even installing solar panels, reducing the need for human intervention and cutting costs. Drones equipped with artificial intelligence (AI) may soon monitor solar cells in real-time, identifying issues instantly and alerting controllers to take preventive measures—ultimately enhancing system reliability and minimising outages.

Drones are pivotal in lowering solar panel maintenance costs by boosting speed, accuracy, and safety. With routine checks and proactive maintenance, solar panels can operate at peak levels, reducing the frequency of costly repairs and replacements. The potential of drone technology in solar energy is promising; it aims to revolutionise installation, maintenance, and monitoring, making it more accessible, affordable, and sustainable. As drone and software advancements continue, they will drive the efficiency and effectiveness of solar systems, shaping a more sustainable energy future.

Infrastructure Inspections

Establishing robust standards is crucial for leveraging drone inspection technology to transform asset management. Creating clear benchmarks ensures that only qualified professionals conduct drone inspections, preventing unqualified operators from undermining the sector’s performance. It is equally essential that drone inspection teams adhere to guidelines from recognised organisations such as SNZ, WorkSafe, Energy Safety, CAA, Maritime NZ, MBIE, EPA, NZTA, NZTF, MPI and others.

Highway and Road Inspections

Drones are now the most effective tool for inspecting highways, roads, streets, and avenues, offering more excellent coverage in less time than traditional methods. Advances in drone technology enable efficient inspections of re-paving, curb maintenance, lighting, gutters, and culverts. The comprehensive data collected by drones can be utilised by engineers, architects, and municipal civil engineers to develop detailed 3D digital models. These models assist urban planning, disaster simulation, and scalable infrastructure development.

Enhancing Road Infrastructure

The global demand to extend the lifespan and usability of highway infrastructure has driven the adoption of innovative technologies for monitoring road conditions, assessing damage levels, and analysing maintenance needs. UAVs can safely inspect and measure road distress more quickly and accurately than manual techniques. Digital images captured by drones can be easily analysed using object recognition software and AI for distress detection and roadway assessment. This technology overcomes many drawbacks of traditional methods, which are often time-consuming, labour-intensive, and subjective.

Roofing and Building Facade Inspections

Roofing and building enclosure professionals face challenges when inspecting difficult-to-reach areas such as church steeples, clock towers, or steep multi-story roofs. Traditional methods like boom lifts, binoculars, or rope access can provide limited access, poor viewing angles, and pose safety risks. Unmanned aerial vehicles now facilitate visual observations and condition assessments of roofing and building facades. Drone inspections are typically cost-effective, faster, and safer than traditional visual evaluation methods.

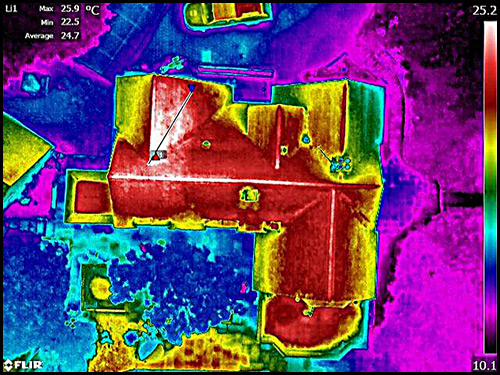

Thermal and Thermographic Imaging

Thermal imagery enhances building condition assessments by revealing excessive temperature differentials that indicate problem areas, uncovering hidden moisture damage, and identifying heat leakage through infrared photos. Our drones can capture high-resolution infrared images, allowing you to easily spot anomalies such as water damage, heat leakage, or other potential issues. Early detection of rooftop problems prevents costly leaks, mould, and rot repairs. Drone-based rooftop inspections offer a faster, safer, and more efficient way to gather valuable data, reducing liability risks and ensuring quicker turnaround times.

Building Glazing Inspections

Modern commercial buildings often feature extensive glass elements, including storefronts, doors, wall-to-ceiling windows, and skylights. While aesthetically pleasing, these glass components can increase energy costs and vulnerability to damage, posing safety concerns for occupants. Building glazing inspections using drones ensure that glazing is well-protected, preventing potential issues before they arise.

Topographical Surveys and Construction Monitoring

Drones are instrumental in topographical surveys, construction monitoring, and ground surveying. They eliminate the need for expensive scaffolding and dangerous ladders, enhancing safety and saving costs. A drone can quickly survey an entire site or building, capturing images from previously difficult angles and complex structures. LiDAR surveys conducted by drones are feasible day or night and in low-light conditions. They can penetrate dense vegetation areas—tasks that would be time-consuming, costly, and potentially unsafe using traditional methods.

Conclusion

Drone inspection technology revolutionises asset management across various sectors by enhancing safety, efficiency, and accuracy. By adhering to established standards and utilising advanced technologies like thermal imaging and LiDAR, drones provide comprehensive solutions for infrastructure inspections. As drone technology continues to evolve, its applications in asset management, road infrastructure, building inspections, and construction monitoring will only become more integral to maintaining and improving our built environment.

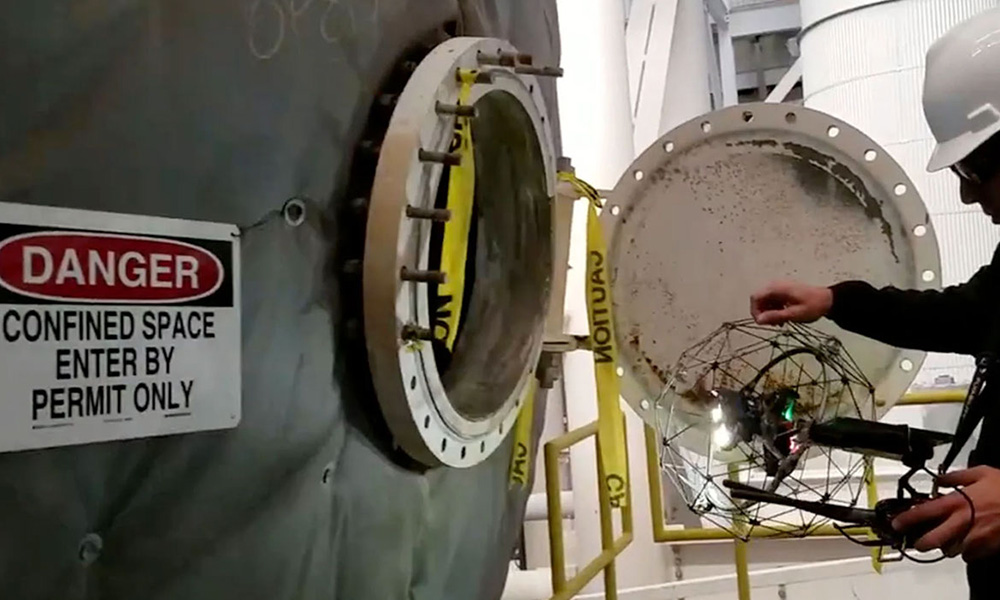

Internal Inspections

Drones designed for industrial inspections are revolutionising the way internal assessments of silos, boilers, pipelines, and other confined spaces are conducted, particularly when combined with Non-Destructive Testing (NDT) methods. These advanced UAVs are equipped with collision-resistant technology and high-definition imaging capabilities, making them ideal for navigating inside complex structures where traditional inspection methods pose significant risks and logistical challenges. By integrating NDT techniques, drones can provide detailed evaluations of structural integrity without compromising the inspected assets, allowing for safer, more efficient, and more thorough assessments.

Key Benefits:

Enhanced Safety: Drones significantly reduce the need for personnel to enter potentially hazardous environments. Traditional inspection methods often require confined space entry, scaffolding, or rope access, increasing the risk of accidents. Inspections can be performed remotely using drones, safeguarding workers and minimising exposure to dangerous conditions such as toxic atmospheres, heights, and restricted spaces.

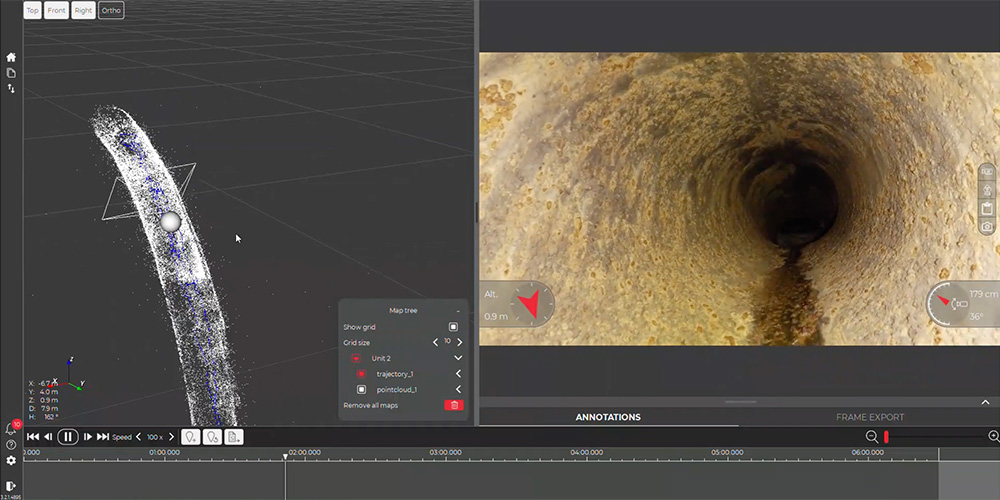

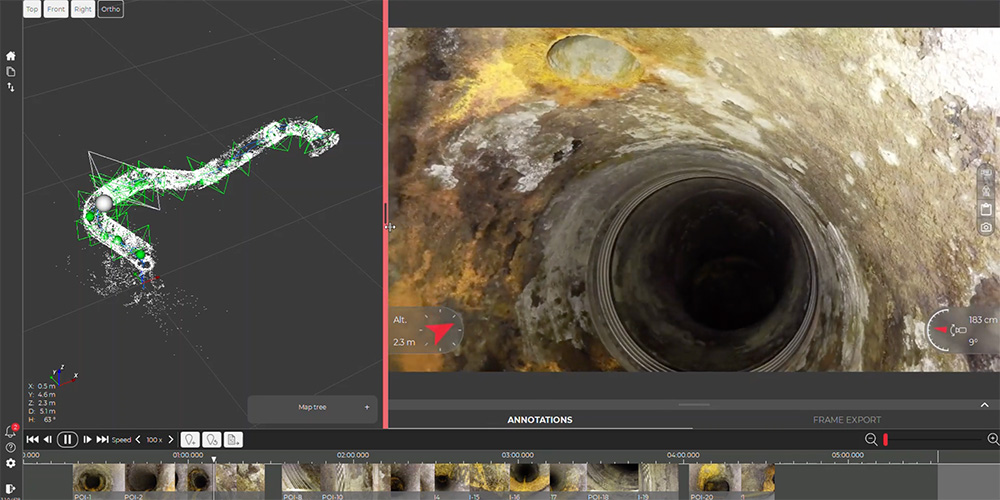

Comprehensive Visual Data: Equipped with high-definition cameras and advanced sensing technologies, drones capture precise, high-quality visual documentation of conditions inside silos or wind turbines, including hard-to-reach areas. This allows for identifying structural issues like corrosion, wear, residue buildup, and cracks, enabling predictive maintenance and preventing costly downtimes.

Reduced Downtime and Costs: By eliminating the need for extensive setup, entry permits, and safety protocols required for manual inspections, drone inspections significantly reduce inspection time and associated costs. Real-time data transmission allows operators to make immediate assessments, expediting decision-making and minimising disruptions to operations.

3D Mapping and Measurement: With onboard LiDAR or similar sensing technologies, drones can generate detailed 3D maps of internal structures. This capability supports spatial measurements, volume calculations, and condition assessments, facilitating better asset management and planning. The 3D models can also serve as benchmarks for future inspections, enabling comparative analysis over time.

Operational Efficiency: Drones are highly maneuverable, making them efficient for routine checks or detailed inspections in tight and complex spaces. Operators can quickly navigate obstacles and focus on specific areas of interest, such as welds, seams, or high-wear zones. This flexibility translates to thorough inspections completed in less time, improving maintenance planning and operational uptime.

Typical Applications:

- Corrosion and Crack Detection: Identify structural weaknesses that could compromise the integrity of the silo or vat.

- Residual Material Assessment: Detect leftover materials or buildup that can impact quality or safety standards.

- Structural Condition Monitoring: Conduct routine inspections to document wear and assess the need for maintenance or repairs.

Summary

Using drones for internal inspections of silos, vats, pipelines, boilers, heat exchangers, wind turbines, HVAC systems, chimneys, and wastewater treatment facilities, among others, provides a safer, more efficient, and cost-effective solution compared to traditional methods. By integrating Non-Destructive Testing (NDT) techniques, these drones enhance the inspection process by allowing detailed structural integrity evaluations without damaging the examined assets. Their robust imaging capabilities and 3D mapping technology enable thorough inspections, while their design makes them suitable for challenging confined spaces. This innovative approach helps industries maintain assets effectively, reduce downtime, and ensure worker safety.