Inspections

Reduce Risk, Time & Cost

Incredible Group’s commercial drones and CAA Part 102 Certified drone operators vastly reduce the risk

and time involved in inspections, compared to physical inspections. Whether you need regular maintenance,

inspections/surveys, an urgent or emergency response, we have you covered – Incredible Group is on call 24/7

Safe, accurate & cost effective: drone Aerial Inspections & Surveys NZ-wide.

We obtain all Permissions required, e.g. from local authorities & airfields.

- Buildings, Assets, Utilities & Infrastructure

- Thermal Imaging (Thermographic Imaging)

- CAA Part 102 UAV Certification

- Full Aviation & $10M Public Liability Insurance

- 11,900+ Safety Verified logged flights

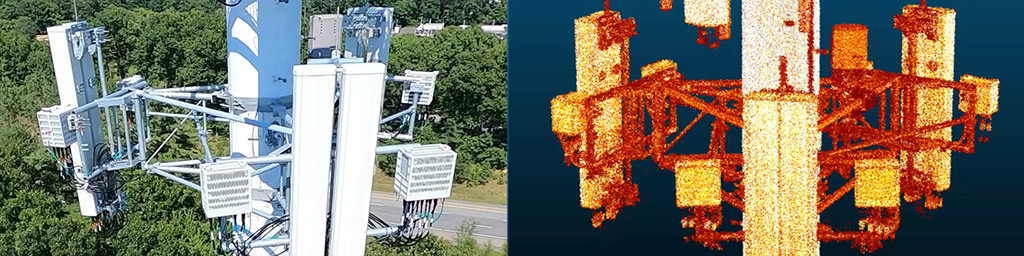

Cell Tower Inspections

Drone technology is disrupting entire industries, and it’s finding its use in the telecommunication industry.

Due to their nature, cell towers inspection are a difficult endeavour. In order to perform a cellular tower

inspection, workers have to risk their lives, potentially disrupt tower performance, and climb high-rise

platforms. With drones, there is no need to cause downtime or endanger workers.

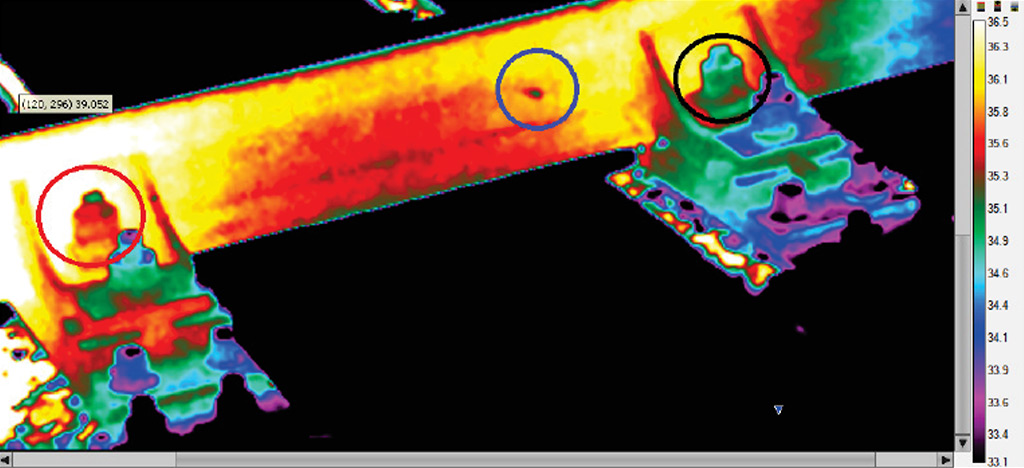

Drones can capture high-resolution images & videos in a matter of minutes. The footage can be zoomed in and

any faults on tower or antennas can be easily detected. Thermal imagery cameras can be used to detect any

energy loss and potential performance issues. There are certain pieces of the cell tower that are expected to

produce a certain amount of heat. Thermal sensors can determine if this equipment is within tolerances

regarding heat production. They can also show the maintenance team where potential problems may lie.

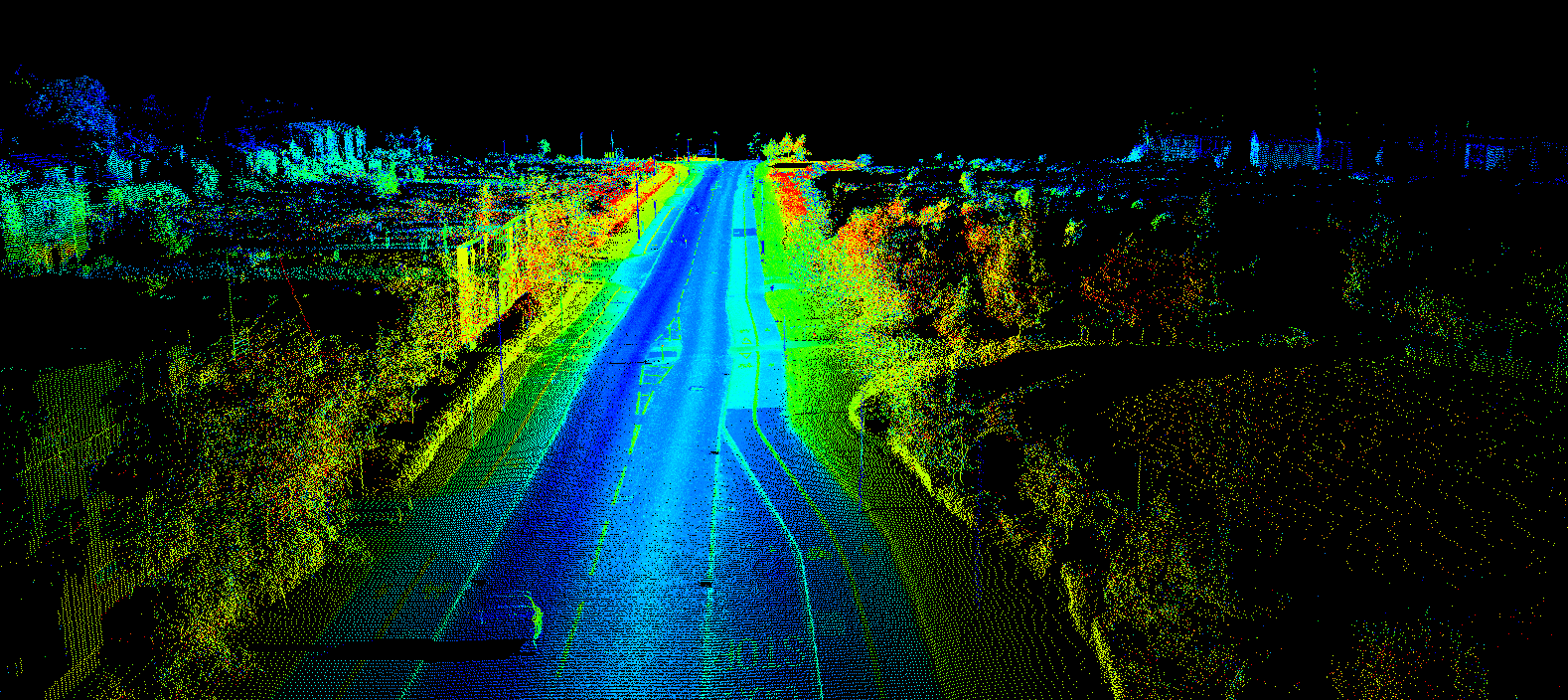

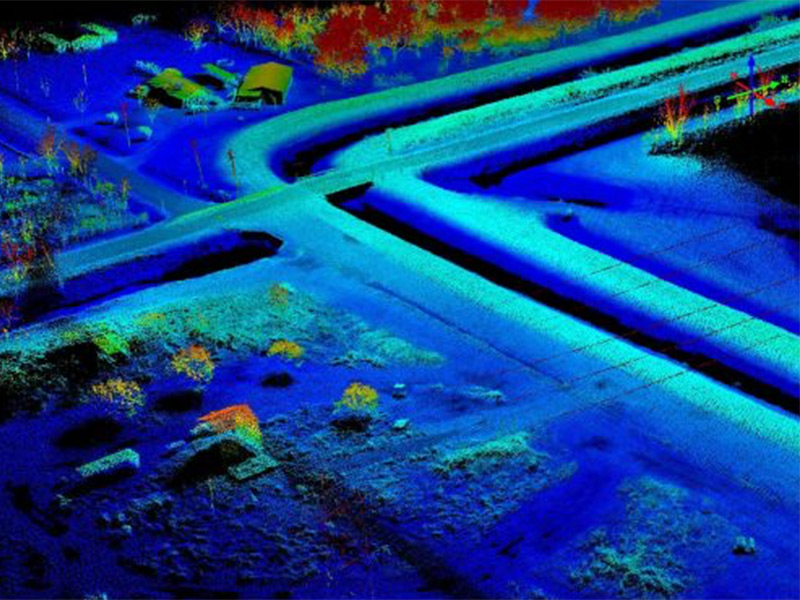

Dedicated LiDAR sensors employ the use of laser emitted light. This, in turn, produces a rather rich data set

that can be used in the production of high-resolution maps, as well as detailed 3D models of the entire site, or

just the tower itself. Drone LiDAR collection sets yield the highest quality data in form of a point cloud. This

point cloud can effectively measure hundreds of points per square meter of space measured at a vertical

elevation accuracy of 2 to 3 centimetres. This allows for a precise measurements purely based on the

inspection data.

When performing these drone cell towers inspections, the imagery and data packages can more than pay for

the service. Also, by using a drone, you are getting a permanent record of the inspection that can be referred to

time and time again — unlike when there are only the inspector’s eyes for information.

Using drone technology for cell tower inspections we can virtually eliminate accidents that are incurred by the

dangers of climbing to inspect the tower. Inspect your telco cell towers without danger to employees and

quickly detect malfunctions

Power Lines Inspections

More and more utilities see the advantages of implementing drone technology in power line inspections.

One of the most useful features of advanced drone technology is the possibility to entrust the drone with the

inspection of power lines in areas that are difficult to access. Beyond Visual Line of Sight operations (BVLOS)

allow the pilot to fly an unmanned aircraft through areas which are out of the pilot’s sight. Although this requires

a higher qualified and more experienced pilot, as well as more advanced licenses and authorisations, it allows

you to access areas that are difficult and risk-filled to inspect manually. A drone can navigate by instruments

and is not reliant on perfect weather conditions to carry out its operation.

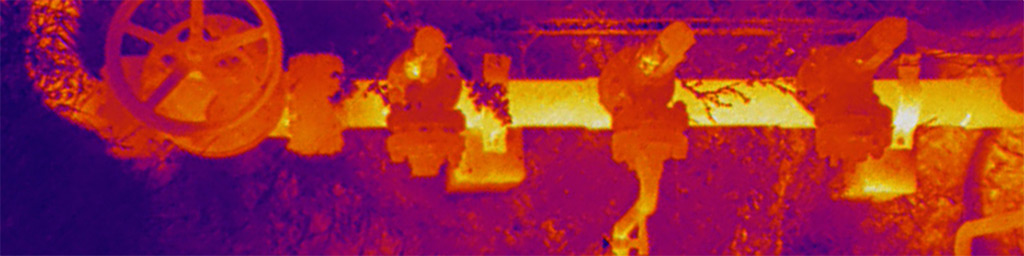

Drones can be used to inspect power lines and power pylons for bird’s nests, lightning strikes, rust/corrosion

and damaged bolts. Our drone solution system takes into account the magnetic interference of the power lines

which affects the drone compass. Therefore, we can fly extremely close to the power lines, and as a result

provide high resolution images and data, useful in the optimisation of your maintenance plan.

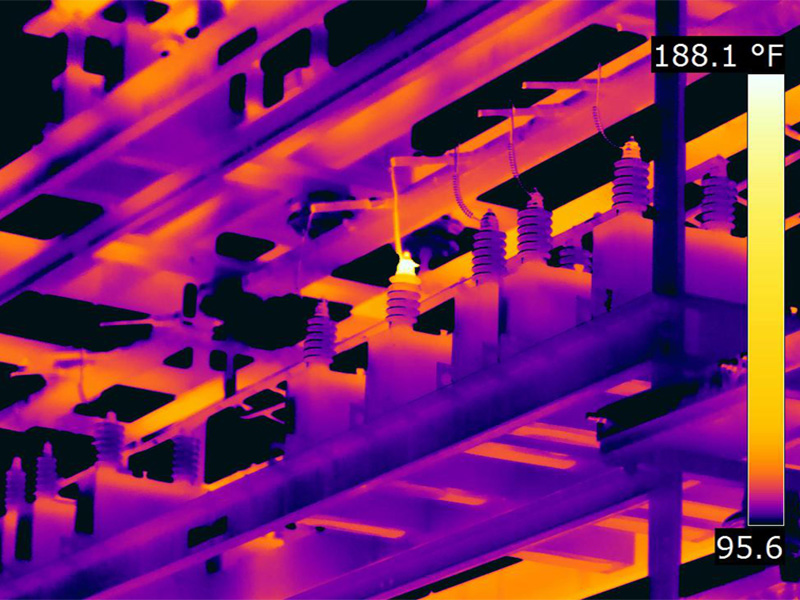

The benefits of catching hot spots early include extending the life of otherwise well functioning equipment;

prevention of equipment failures that could lead to widespread outages; and reduction of costs through

maintenance as opposed to replacement of damaged equipment. Thermal imaging really allows you to see

what the naked eye can’t see. It allows you to fix these problems before a failure, and it will be a huge benefit

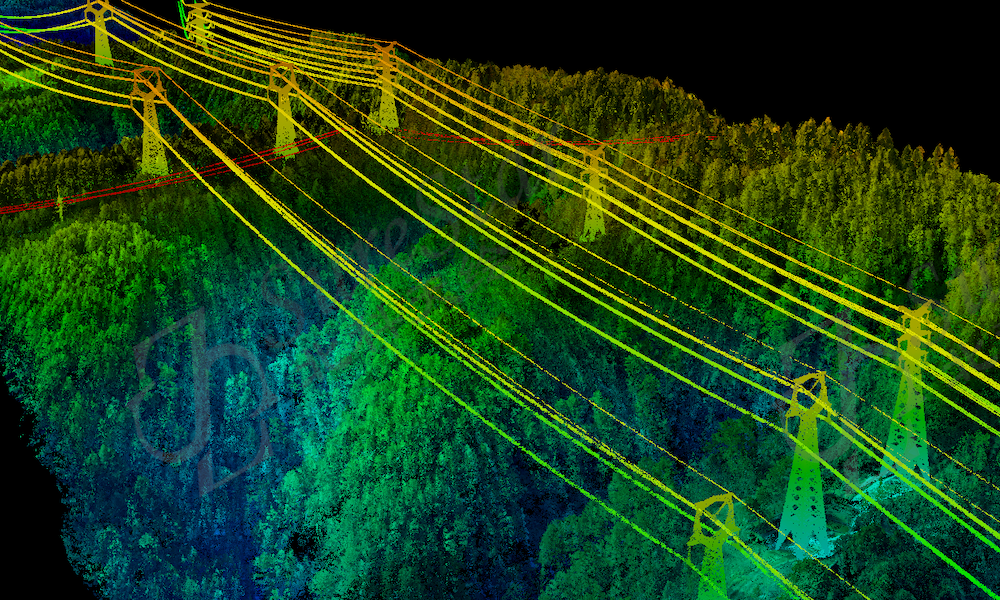

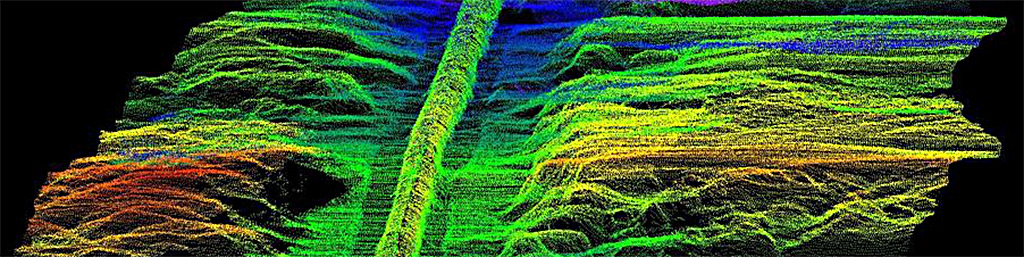

LiDAR use in power line inspection offers unique advantages. LiDAR point clouds and 3D maps allow grid

operators to measure the distance between the foliage, different vegetation and power lines. This in turn allows

them to make well-informed decisions and predict the areas that will become problematic in the near future.

Instead of doing large scale clearing operations, the grid operators can focus on the areas that pose the largest

threat to the stability of their power line network.

to your company.

In post-storm observations, LiDAR power line inspections allow to detect tilting trees that are dangerously

close to the power lines or might pose a threat, should they fall down. This again helps grid operators to make

pre-emptive decisions and take action, before storm-damaged trees might fall and cause blackouts. LiDAR

power line inspections enable the grid operators to save time, money and loss of revenue due to blackouts

when taking the right actions based on good information.

RGB data analysis relies on photos taken by drones during the data collection phase. Both distribution system

operators (DSOs) and transmission system operators (TSOs) use RGB photos to detect defects that would

otherwise be hard to see from the ground. As drones enable the inspection teams to get a top-down view of

the power poles and lines, they get a total overview of the state of the asset. Broken wires, rust on details and

assets, chipped and bent insulators – these are just some of the defects that are often detected from RGB

photos. The efficiency of being able to document the state of an asset through a few images at an

unprecedented speed makes this inspection method accessible to more electric utilities.

Using infrared images in power line inspection data analysis is most often done to detect overheating elements

and the corona effect. Overheating elements are a clear indication of a possible near future breakdown of the

asset and thus have to be fixed urgently. Detecting the overheating elements allows the grid operators to take

preemptive measures to avoid blackouts and grid downtime. When analysing the infrared data, it is quite easy

to detect overheating elements on the pictures, as they are much hotter than surrounding parts and thus glow

brightly in the thermal images.

Railways Inspections

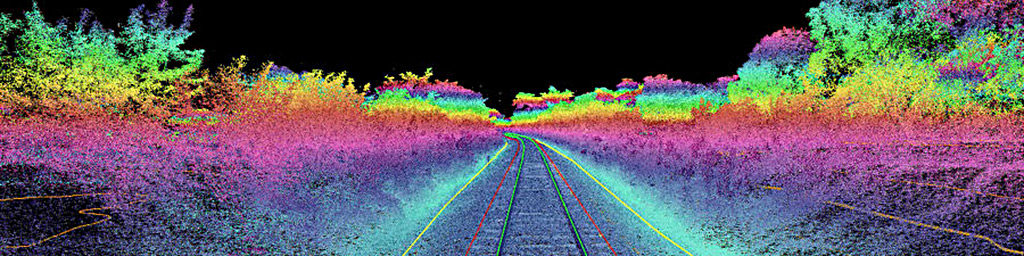

Drones in the Railway industry have become a necessary equipment for stable railway inspection systems.

They are employed to monitor significant railway infrastructures, such as high-voltage electrical lines, railway

catenary lines, and even tracks and switching points. With drone technology’s assistance, extensive drone

imagery is obtained, to magnify the process of defect detections, crack detections, and additional dangers

quickly. The more frequent the inspections are, the higher railway security, dependability, and scheduled

performance there is. Higher productivity would, in return, reduce expenses and warrant overall productivity

from the industry.

Deformed rails and broken sleepers are a few examples of potential dangers, and if not resolved soon, they

could cause severe damage. Defects such as cracking, peeling, scratches, folds, broken rails, scars, etc. are

accurately recognised. UAVs have evolved to fill gaps of inspections of conventional railway inspection

systems and developed the operation with fewer interruptions, more effectiveness, and efficiency.

Drone data has become almost every industry’s most trustworthy source of information and enables active

decision-making. Since a land boundary can be placed over an orthomosaic, railway firms can recognize land

acquisition concerns or any collisions with existing construction projects. During drone surveys, valuable

information about the surroundings are gathered, and any interferences recognised can be resolved in time.

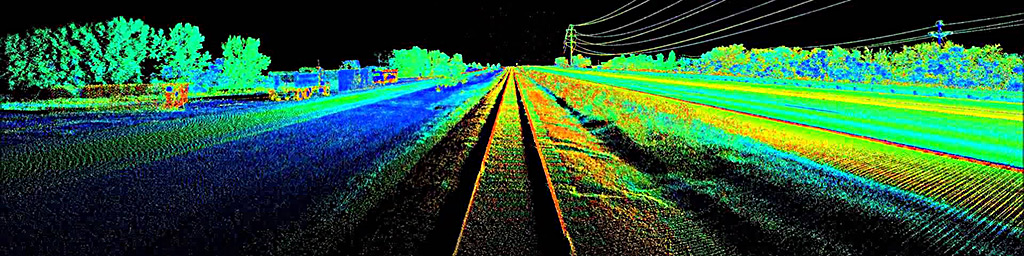

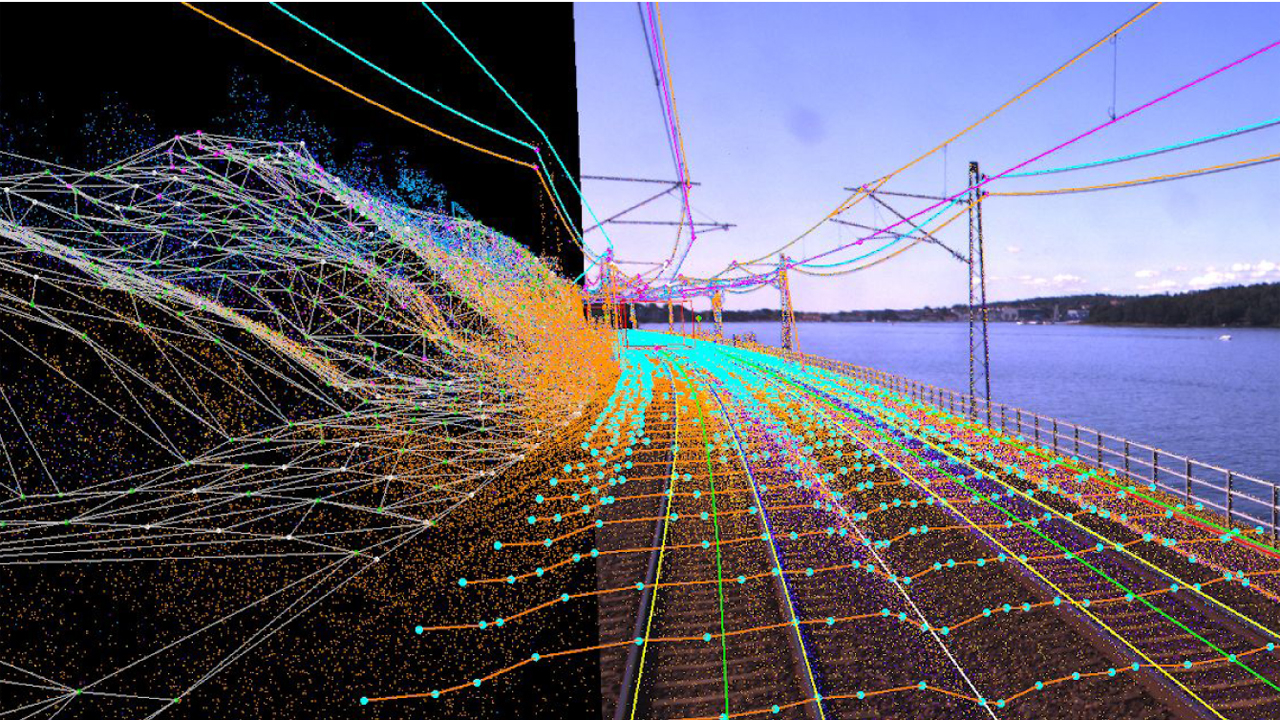

LiDAR system precisely locates signage, crossings, wayside equipment, culverts, tunnels, vegetation, and

other clearances and track features. Real-time LiDAR point cloud generation supports the continuous

three-dimensional, right-of-way clearance measurements and alerts. Crossing sight-distance maps can be

readily constructed from the LiDAR data to improve crossing safety and support an investigation in the event of

an accident. Clients can use the point cloud data to evaluate the profile and slopes of longitudinal drainage

ditches and identify areas requiring maintenance. Multiple passes can provide validation of ditch maintenance

work and can measure movement and changes in embankments and tunnel walls, helping identify features that

warrant follow-up geotechnical assessment. The LiDAR system identifies areas that require vegetation

management, and subsequent passes validate the effectiveness of vegetation management work.

Performing traditional inspections of a railway is time consuming and difficult to manage in high traffic areas.

Using our Aerial Imaging System allows railways to automatically collect continuous images of the track from a

moving platform. The ability to store these geo-referenced images allows for any area in question to be

evaluated from the office. Our expertise with high-resolution camera systems and advanced image processing

algorithms result in systems with extremely reliable image acquisition and processing capabilities.

Oil & Gas Inspections

Inspection drones are today behaving like a scalable technology that are not only transforming the businesses

of high value asset inspection but can also be expected to transform the entire businesses / operations related

to large infrastructure projects, especially in energy sector (oil & gas, renewable, power plants, petrochemical

plants etc), where sustainability and asset management is considered to be part and parcel of energy delivery –

the core function of Energy Sector Organisations.

Drone technology and data analysis software have been moving from infancy to maturity at a remarkable pace

and this indicates an inevitable transformation in the process of asset management. There are professionals in

the industry who envision a day when offshore platforms (wind turbines, oil rigs, production platforms, etc)

have hangers for a drone and the drone shall be programmed to fly around the asset facilities at set intervals

(perhaps daily, monthly or quarterly) to capture data and then transmit the anomalous conditions to the control

room for analysis.

The detection of methane gas leaks, which are common and a challenge in the oil and gas industry, is

important aspect of inspections. Usually, the methane gas leaks present risks to the community, users, workers

and the environment. The oil and gas companies have the responsibility of preventing and addressing any

leaks in the upstream, midstream or downstream components of production and distribution systems. While

traditional methods have been used for a long time, they are slow, risky and costly. Further, inspection workers

accessing contaminated areas face a wide range of risks when exposed for long periods. To overcome some of

these and other challenges, companies can deploy drones, which provide faster, cost-effective and safe

unmanned aerial methane detection solution. A typical application involves attaching a gas sensor to the drone

integrated with image, video and location and other sensors or technologies that support the identification of

leaking sections of the infrastructure.

Current inspection techniques that allow access to unreachable areas require manpower, equipment

shutdowns, and a level of unnecessary risk. Our UAV’s are fitted with high-resolution cameras and allows

inspectors to access previously inaccessible locations, reducing reliance on physical inspection processes.

Footage can be live-streamed to specialists working remotely, and with fewer personnel needed on-site, there’s

improved safety and less disruption. This drone technology enables inspections of small, hazardous or

inaccessible locations to happen effectively, efficiently, and safely.

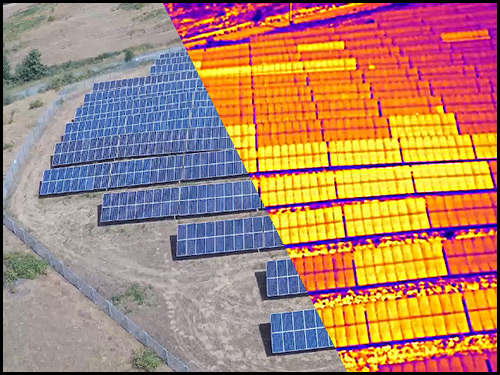

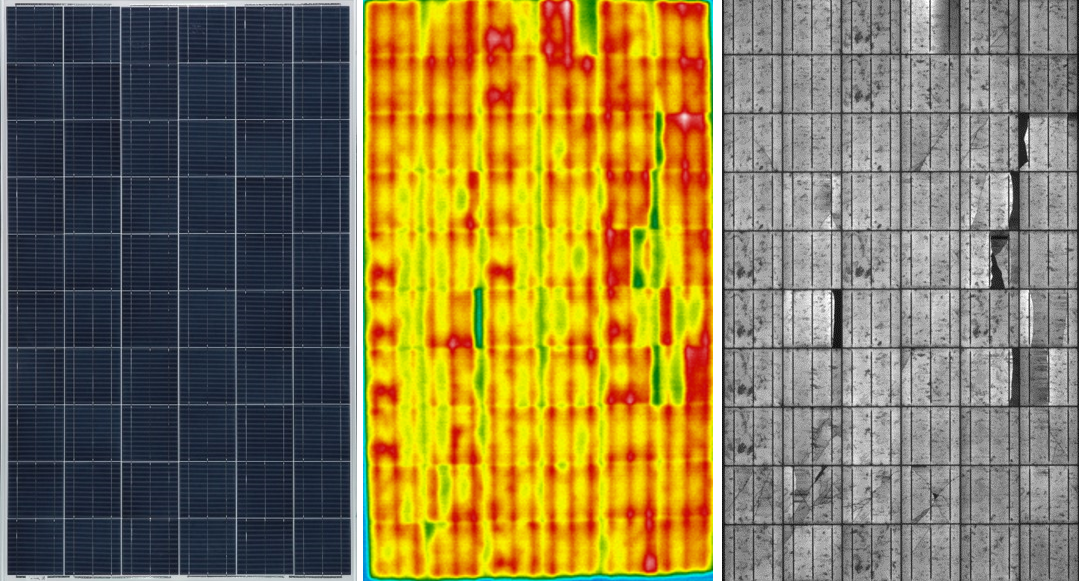

Solar Panels Inspections

Aerial inspections enable you to document and diagnose panel degradation, scan inverters and data capture

vegetation management. Traditional inspections are conducted and are limited to a sample of the site while

drones oversee the entire solar project.

UAV technologies for solar panel are ideal for energy providers, renewable energy asset managers, and

governmental agencies focused on sustainable and tailored energy solutions, as well as looking to improve the

reliability and efficiency of their installations. Traditional manual inspections often involve workers climbing onto

rooftops, navigating challenging terrain, or being exposed to harsh weather conditions such as extreme heat.

Using drones eliminates these safety risks by performing inspections remotely. Drone inspections are

cost-effective when compared to time-consuming manual inspections, which require expensive equipment.

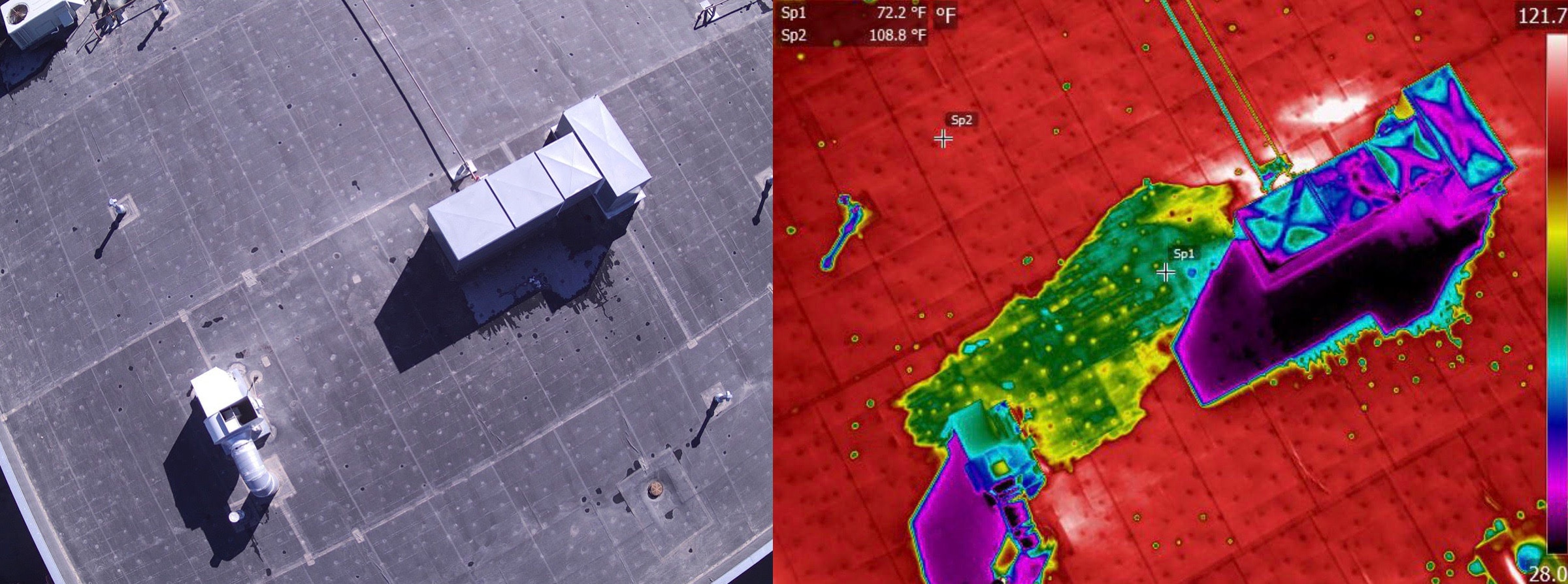

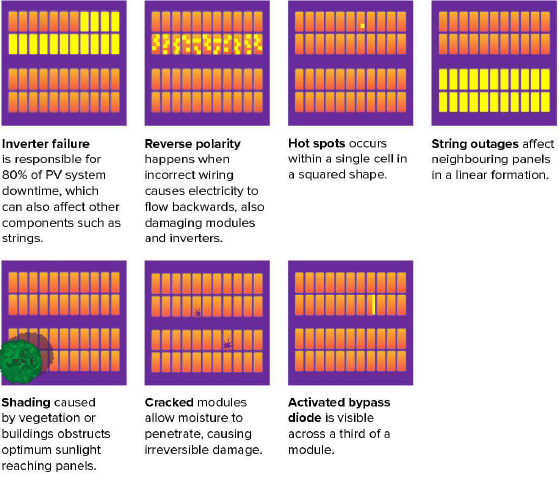

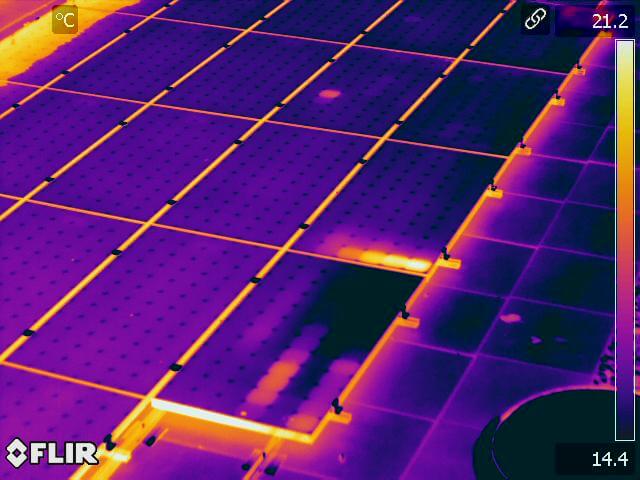

Drone inspections utilize aerial thermal imaging to locate and diagnose faults where electricity production has

visibly dropped, allowing owners to act on operational inefficiencies and optimize power generation. Anomalies

include cell and string defects, defective diodes, bird or snail debris, inverter problems and short circuits. In

addition to being quicker and more precise than manual checks, drones also lessen the possibility of technician

harm. Drones can examine large solar systems swiftly and without the need for cumbersome tools due to their

ability to access difficult-to-reach regions. Furthermore, compared to conventional manual inspections, drones

can rapidly cover vast regions, saving time and resources. They can also access places that are challenging for

techs to get to, like rooftops or sizable solar fields.

Drone-based solar panel inspection and tracking offer a quick, precise, and economical way to guarantee the

best performance possible from solar panels. Potential problems can be found early on with routine checks

and tracking, leading to more efficient and economical solar energy systems. Regular thermal inspections can

identify problems before they become severe or identify trends in certain anomaly types over time, allowing for

timely maintenance and avoiding more costly repairs or replacements.

Drone technology for solar energy has a bright future ahead of it, with many developments and innovations

anticipated to boost the efficacy and efficiency of solar installation and upkeep. The examination and

placement of solar panels have already benefited from improvements in drone hardware and software’s

accuracy and precision. Future advancements could make it possible for drones to independently carry out

maintenance and install solar panels without the need for human assistance, cutting costs and increasing

productivity. Additionally, drones with artificial intelligence (AI) could watch solar cells in real-time, identifying

problems and notifying controllers to take preventative action. By doing this, outages would be reduced and

solar energy systems’ total performance would be enhanced.

By increasing speed, accuracy, and safety, the use of drones in solar panel maintenance can greatly lower costs. Solar panels can function at their peak levels with routine checks and proactive maintenance, which lowers the need for pricey repairs and replacements. Drone technology in solar energy has promising future possibilities. Drones have the ability to completely transform the way solar energy is installed, kept, and monitored, making it more widely available, reasonably priced, and sustainably produced. Drone technology and software advances will continue to improve solar energy systems’ efficacy and effectiveness, paving the way for a more accessible, cheap, and sustainable energy future.

Infrastructure Inspections

Equally important aspect of drone inspection technology to transform asset management is to create new

standards that can apply in facilitation of drone inspection and bench marks to avoid non-qualified players to

adversely affect this business sector performance. In this regards, equally important is the aspect that the

drone inspection team which is deployed for inspection should be conversant with guidelines provided by

relevant publications of API, IEC, ISO, NFPA, BS, ASME, CSA, ASTM and the like.

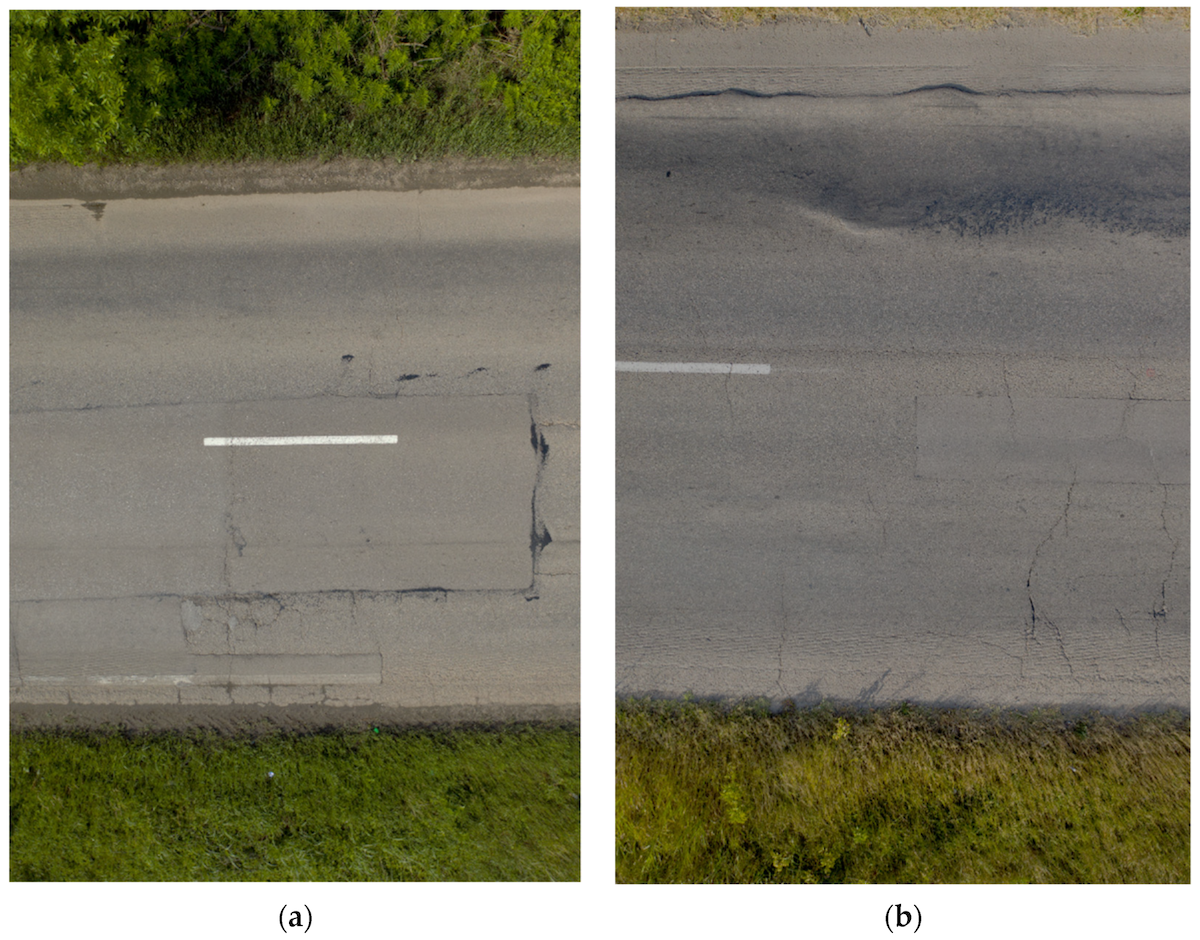

The most effective way to inspect highways, roads, streets and avenues is currently using Drones. It represents

greater reach in less time. To appreciate the advances in the matter of re-paving, maintenance of curbs, lighting

and the condition of the gutters and culverts is now done more efficiently thanks to the Inspection of Highways

and Avenues using Drones. The use of this data can be used by engineers, architects and civil engineering of

the municipalities to develop useful 3D digital models to plan urban growth, simulate catastrophes or simply to

limit measures to scale.

The growing global need to extend the service life and usability of highway infrastructure has led to

investigating innovative new technologies for monitoring road condition, assessing levels of damage, and

analysing maintenance needs. UAVs have the ability to safely inspect and measure distresses faster and more

accurately than traditional manual techniques. Digital images can be easily, clearly, and quickly obtained for

road analysis using UAV’s. These images can be analysed using object recognition software and AI for distress

detection and roadway assessment.

When it comes to monitoring the condition of roads, UAV technology can overcome many of the downsides

associated with traditional methods, which can be time-consuming, labour-intensive and sometimes

subjective.

Roofing and building enclosure professionals are presented with a challenge in getting to a particular wall or

roof for up-close observations such as a church steeple, a clock tower, or a steep slope roof near the top of a

multi-story wall. Often these are observed using boom lifts, binoculars, adjacent buildings or roofs, or utilising

rope access techniques that often provide limited access, poor viewing angles, and at times, unsafe situations.

Today, the use of unmanned aerial vehicles aids in visual observations and condition assessments of roofing

and building facades. In most circumstances, documenting existing conditions with drones can be completed

at a lower cost, faster than traditional methods of visual evaluation, and most importantly, provide a safer

means to complete the work.

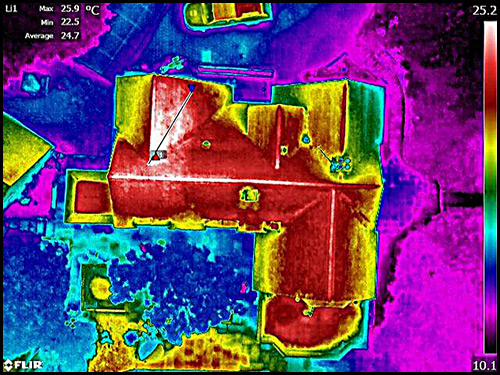

Thermal imagery allows you to truly understand the condition of your building. You can spot excessive

temperature differentials which can indicate problem areas, uncover hidden moisture damage, and identify heat

leakage problems with infrared photos.

Easily assess the condition of your building with thermographic imaging. Our drones can fly over your property

and capture high-resolution infrared photos with high detail. Spot anomalies and identify water damage, heat

leakage, or other potential problems. If left untreated, many rooftop problems can get worse and more costly,

causing leaks, mould, and rot. Performing rooftop inspections with drones is a faster, safer, and more

time-efficient way to gather the valuable data you need. Reduce liability risk and enjoy faster turnaround times.

Most modern commercial buildings have a fair amount of glass, either in storefronts, glass doors,

wall-to-ceiling windows or skylights. Though it is aesthetically desirable, these glass components of a

building’s architecture can lead to higher energy costs and higher susceptibility to damage, creating safety

issues for the building’s tenants. A building glazing inspection is essential in ensuring that your glazing is

well-protected in order to prevent potential problems before they occur.

Drones are used to gauge topography. They can monitor construction progress and carry out ground surveying and eliminate the use of expensive scaffolding and dangerous ladders, making it safe and money saving. Since a drone can fly around an entire site or a building in minutes, inspections are less time consuming. Drones can take photos from previously tricky angles and in complicated structures. LiDAR surveys are possible in day and night in low lightning conditions. LiDAR can penetrate in dense vegetation areas, which would be time-consuming, cost-intensive and potentially unsafe if done by traditional methods.